FLOOR CONSTRUCTIONS & COVERINGS

There are many different types of floor constructions that

underfloor heating can be installed in

Floor constructions

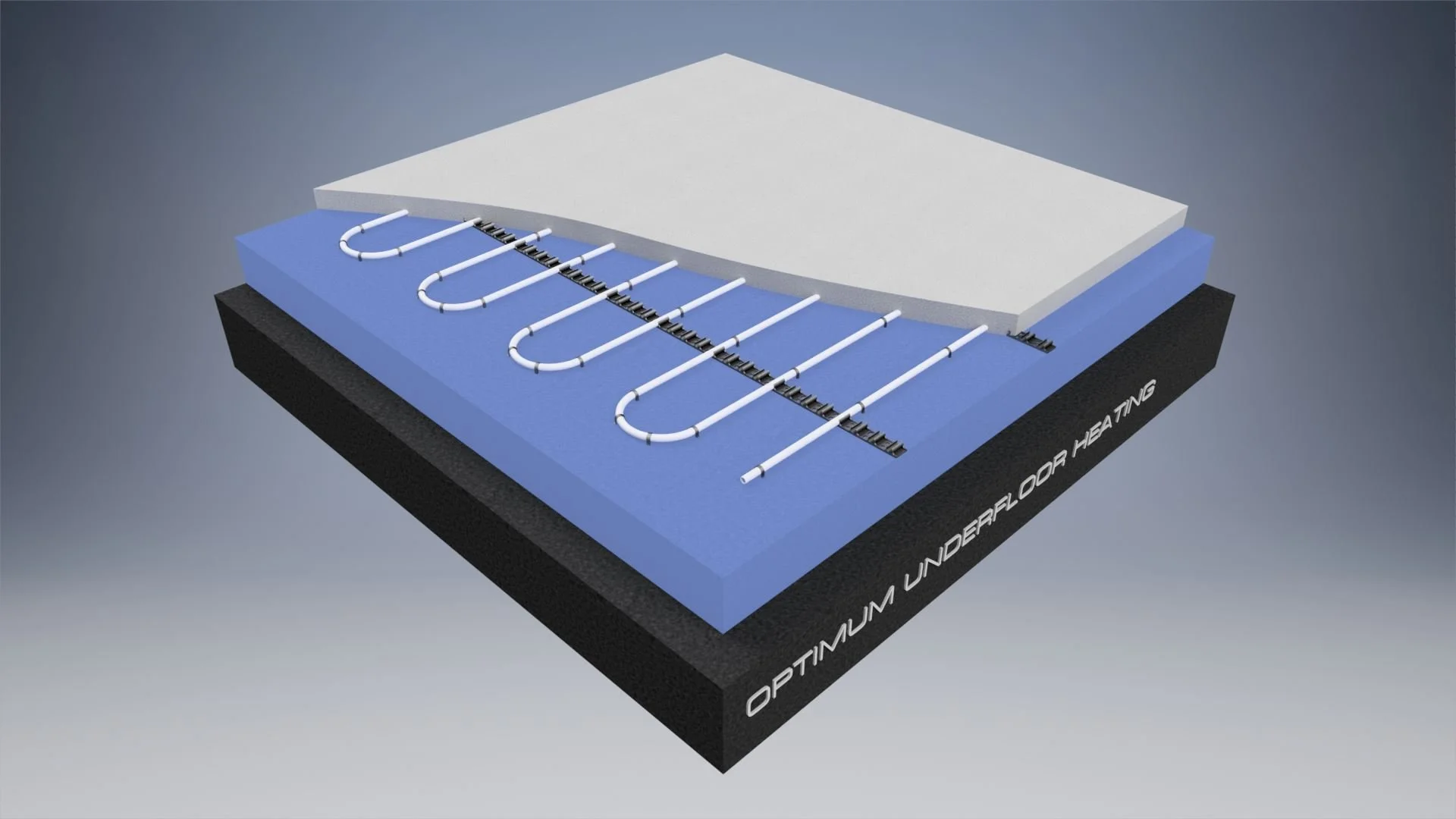

Screed Floor

When installing underfloor heating into a screed floor the pipework is clipped to the insulation layer within the floor structure using fixing rails and plastic staples. We recommend that a high density, flooring grade insulation is installed such as extruded polystyrene (XPS) or polyisocyanurate (PIR) insulation products. If a polyurethane (PUR) insulation product is to be utilised, please advise as extra pipe fixings will be required for securing the pipework. If a standard sand and cement screed is to be poured, Optimum UFH recommend a 65mm depth. However, if a liquid screed is to be used then a lesser depth (minimum 50mm) can be installed. If using a liquid screed, please advise as extra pipe fixings may be required

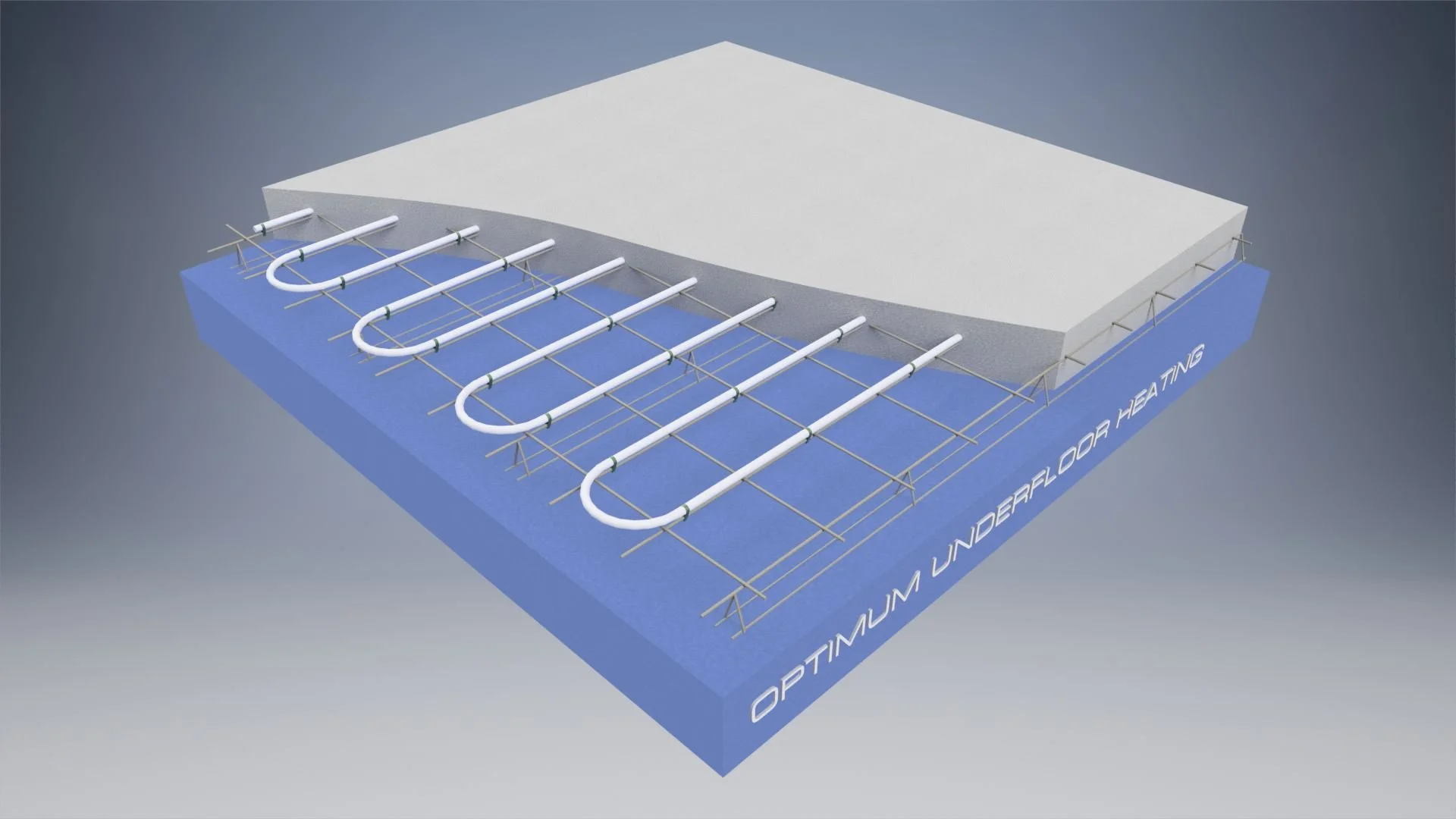

Reinforced Slab Floor

When installing underfloor heating into a reinforced structural slab floor the pipework is tied to the wire mesh within the floor structure plastic coated wire ties. This mesh will then be raised using specific spacers to bring the mesh and underfloor heating pipework into the centre of the concrete slab once poured. Optimum UFH recommend a minimum 40mm cover is provided over the pipework. If there any expansion, construction or crack inducing joints to be made in the floor structure, please advise as extra measures will need to be taken to avoid damaging the pipework.

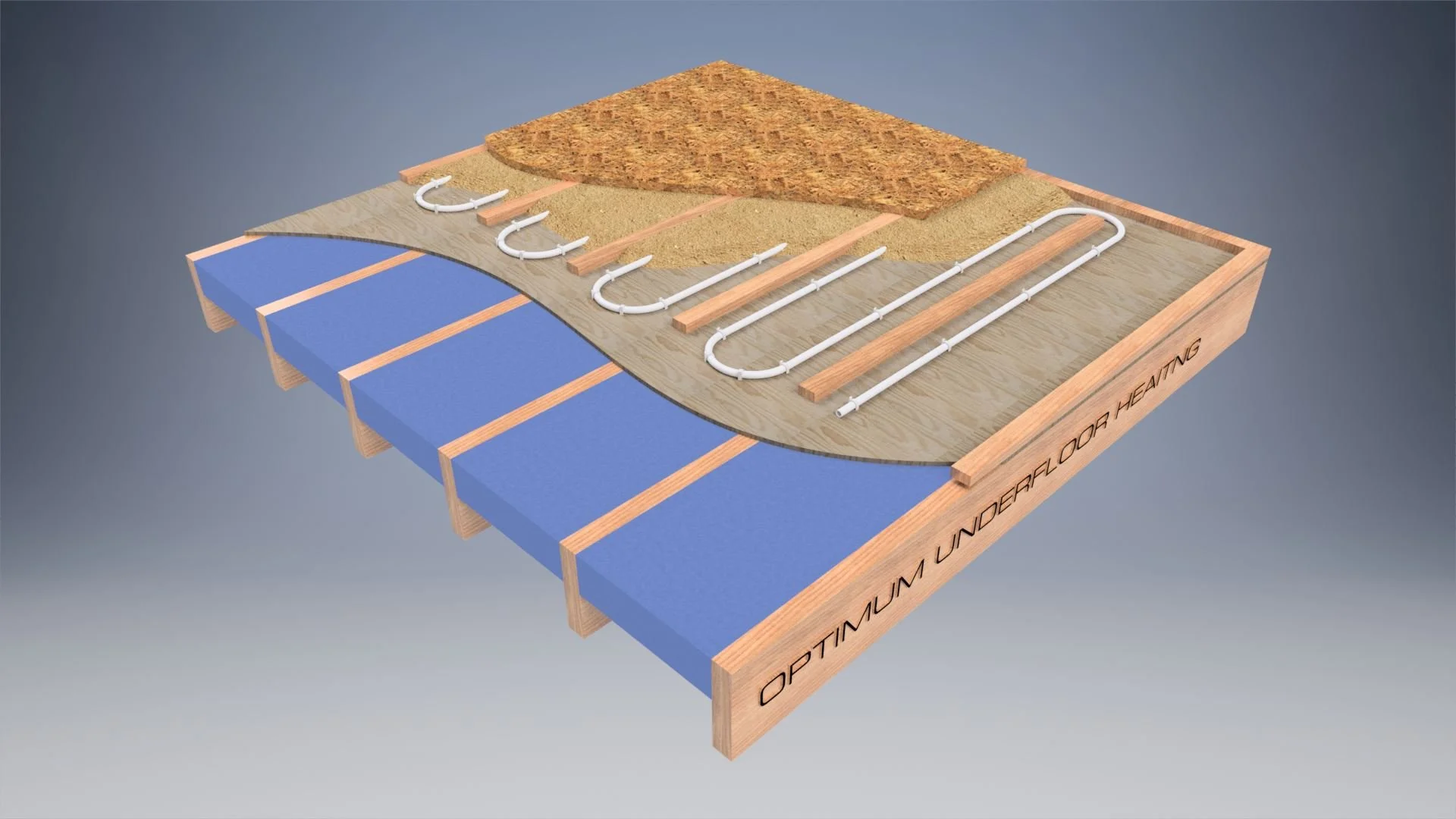

Timber Joist Floor - over the joists method

When installing underfloor heating into a timber joist floor using over the joist method, plywood sheeting is laid over the joists. 25mm high x 50mm wide timber battens are then fixed onto the plywood directly over the joists below. The pipework is clipped to plywood sheeting using u-profile hammer clips. In order to allow good heat transfer through the floor structure, a weak, dry mix of sand and cement, 8 parts sand to 1 part cement, is then packed tight around the pipework and levelled off with the 25mm depth of the timber battens. Rigid, flooring grade insulation must be installed below the plywood sheeting between the joists. This must be secured hard up beneath the plywood to prevent any down draughting. We do not recommend that any glasswool insulation is used, especially on ground floors.

Timber Joist Floor - between the joists method

When installing underfloor heating into a timber joist floor using between the joist method, plywood sheeting is attached between the joists to timber battens that are fixed directly to the joists. Then rigid, flooring grade insulation must be installed on the plywood sheeting between the joists leaving a 25mm gap to the top of the joist. The pipework is clipped to the insulation layer using fixing rails and plastic staples. In order to allow good heat transfer through the floor structure, a weak, dry mix of sand and cement, 8 parts sand to 1 part cement, is then packed tight around the pipework and levelled off with the the timber joist.

Final floor coverings

Ceramic, Slate, Stone and Quarry tiles

Due to there dense make-up, all offer very good heat transfer when laid on top of a concrete floor. It is important to run the floor heating at a low temperature before any floor finishes are installed. This ensures that any remaining moisture within the floor structure is expelled.

Carpets

Carpets can be used over underfloor heating with the following conditions. The carpet and underlay should have a combined tog rating of 1.5 tog or less. There are now underlay's manufactured specifically for use with underfloor heating. Please ensure that any rooms you plan to carpet are highlighted at the design and quote stage.

Vinyl and Linoleum

Both are suitable for use with underfloor heating but should not exceed 5mm in thickness. It is very important if gluing these coverings down that all moisture from the concrete floor is eliminated first. This will ensure that moisture does not form and cause the glue to fail.

Hardwoods

Optimum’s underfloor heating system is always designed to ensure that the maximum permitted surface temperature of hard wood is adhered to. Hardwood should always be checked to ensure its moisture content is below 10% before fitting and that the moisture from the concrete floor is eliminated first.